Why Aluminum Extrusion Die Manufacturers Are Moving to 7-Axis CNC Machining

Why Aluminum Extrusion Die Manufacturers Are Moving to 7-Axis CNC Machining

The aluminum extrusion industry is evolving rapidly. As aluminum profiles become more complex and application requirements continue to rise, aluminum extrusion die manufacturers are facing unprecedented challenges in machining efficiency, accuracy, and safety. Traditional machining solutions based on separate CNC Lathe and milling machines are no longer sufficient. This is why an increasing number of manufacturers are turning to 7-axis CNC machining as a future-ready solution.

Advantages of 7-Axis CNC Machining

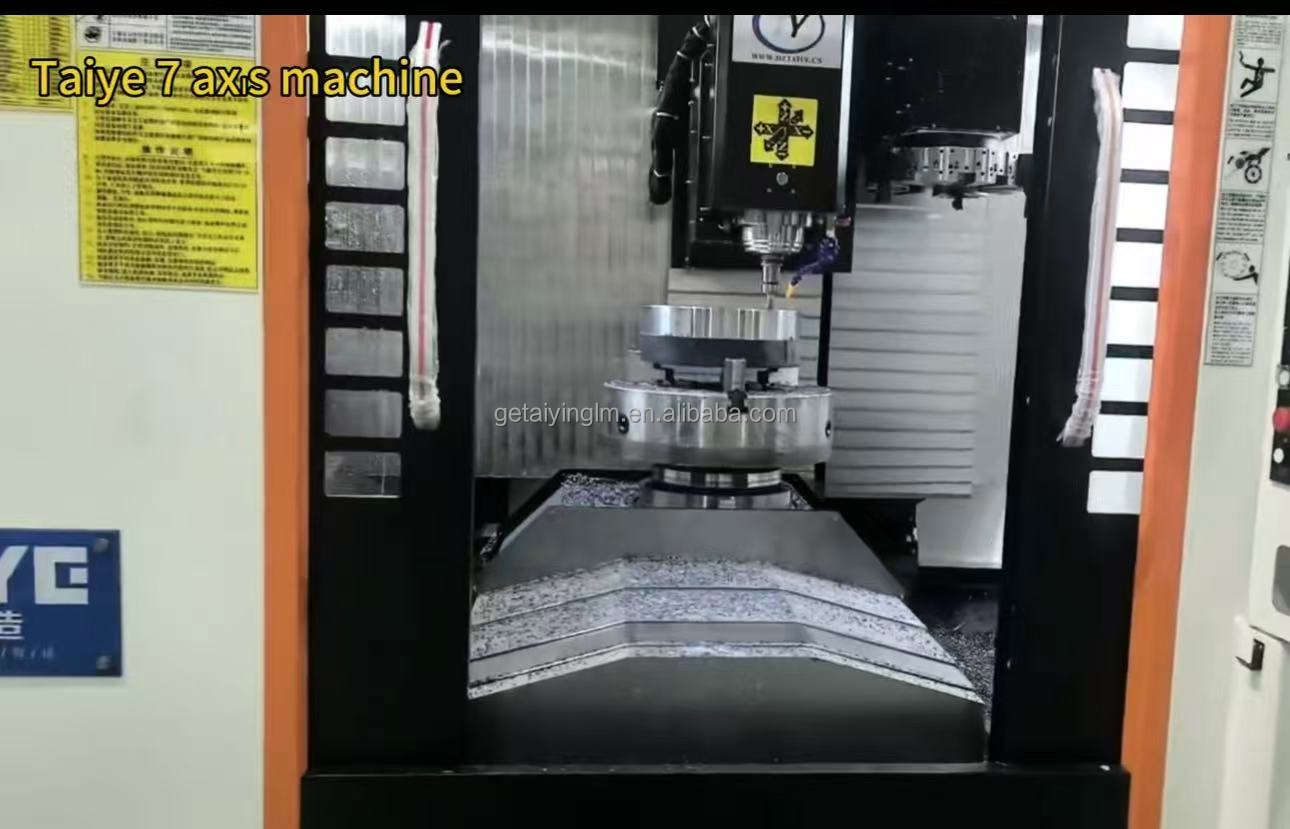

A 7-axis CNC machine integrates turning, milling, drilling, tapping, engraving, and keyway machining into a single platform. By combining CNC Lathe functions with advanced multi-axis machining capabilities, it enables true one-stop machining for aluminum extrusion dies.

?rel=0

Major benefits include:

• Completion of multiple processes in one setup

• Higher machining accuracy and consistency

• Shorter lead times

• Reduced labor intensity

• Improved operational safety

Limitations of Traditional CNC Machining Methods

Modern aluminum extrusion dies are larger, heavier, and more complex than ever before. They often include expanded angles, intricate flow channels, mandrel feeding grooves, water-guiding structures, and side lifting slots. These features require multi-directional machining and precise alignment.

Using conventional CNC machines, manufacturers must rely on multiple setups, repeated clamping, and different machines to complete all required machining processes. This approach leads to:

• Longer production cycles

• Higher risk of machining errors

• Increased labor and handling costs

• Safety concerns when processing large dies

Traditional aluminum extrusion die machining typically involves a CNC Lathe for turning operations and a separate milling machine or machining center for additional features. Even with a 5axis machine, limitations remain when turning and milling must be completed on different platforms.

Key drawbacks include:

• Frequent workpiece transfers

• Accumulated positioning errors

• Complex fixture requirements

• Inefficient use of workshop space

These limitations directly affect productivity and final die quality.

Industry Shift Toward Integrated CNC Solutions

The shift toward 7-axis CNC machining reflects a broader trend in the aluminum extrusion industry: moving from fragmented machining toward integrated, intelligent CNC machine solutions. Manufacturers adopting 7-axis technology gain a competitive edge by improving efficiency while maintaining strict quality standards.

- 3 Axis Vertical Machining Center

- 3 Axis Hard Line Vertical Machining Center

- 3 Axis 2 Linear One Hard Line Vertical Machining Center

- 3 Axis Linear One Line Vertical Machining Center

- Heat Treatment Vacuum Furnace

- Heat Treatment Oil Quenching Vacuum Furnace

- Heat Treatment Air Quenching Vacuum Furnace