How can the side lifting grooves of large aluminum extrusion dies be machined conveniently?

How can the side lifting grooves of large aluminum extrusion dies be machined conveniently?

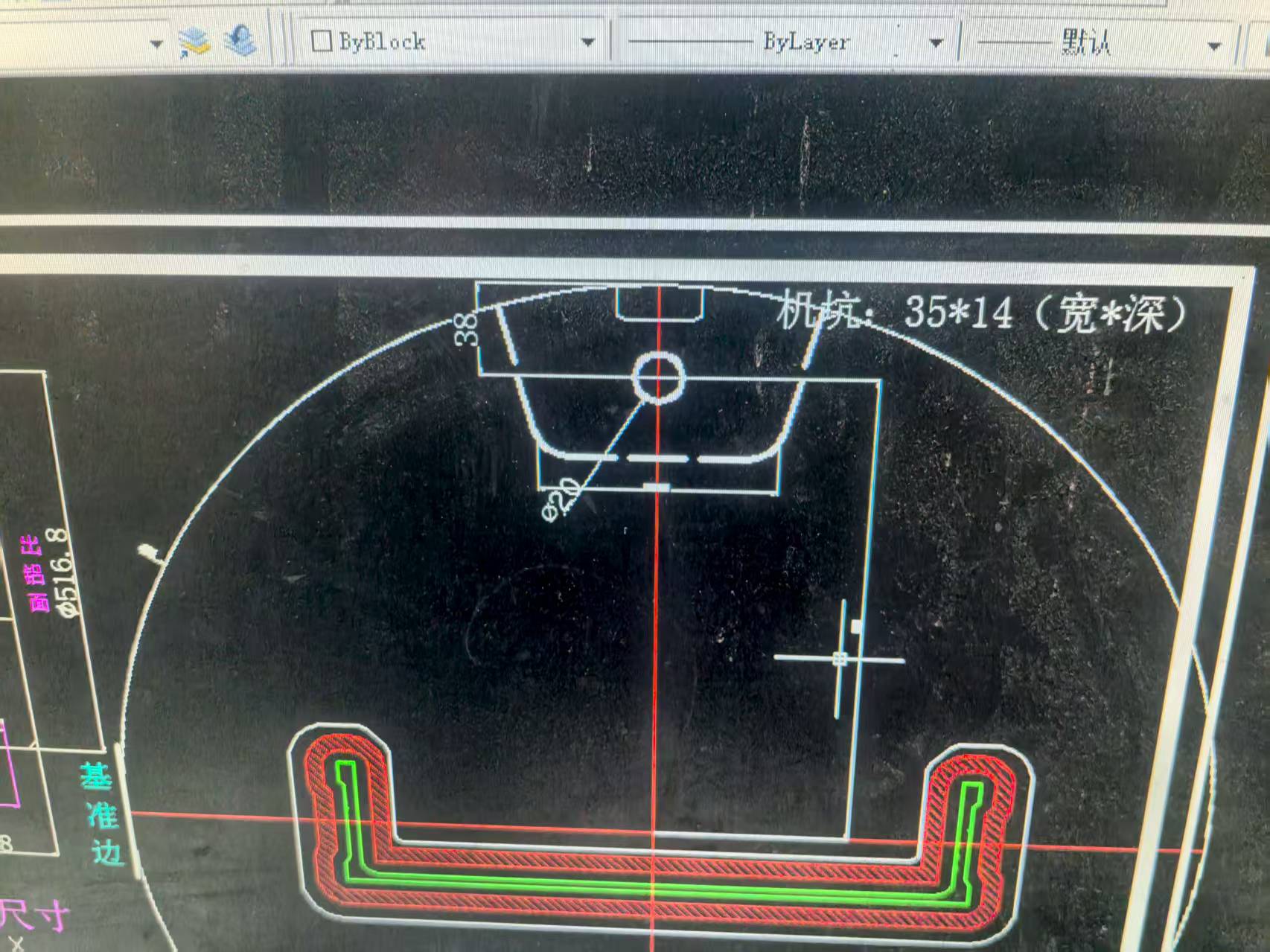

The main difficulties in machining side lifting grooves of large aluminum extrusion die generally include: the large size and heavy weight of the aluminum extrusion die, making clamping and turning difficult; deep grooves with high load-bearing requirements.

By using two types of machines specially developed by Taiye machine for extrusion dies—a 5 axis machine center and a vertical–horizontal machining center—the aluminum extrusion die can be placed flat on the worktable. With the spindle set horizontally for side milling, all machining can be completed in a single setup, ensuring good dimensional symmetry and high machining accuracy of the groove bottom, fillet radii (R angles), and depth. The operation is safe and particularly suitable for machining large aluminum extrusion die.

?rel=0

Key considerations for machining lifting slots on large aluminum extrusion die:

Use combined chamfering cutters. Select end milling with corner radii so that slot milling and edge chamfering can be completed in one operation, eliminating separate chamfering steps and reducing machining time.

The dimensions of the lifting slot must match the specifications of the lifting equipment. The slot depth and width should meet load-bearing requirements to prevent fracture during lifting.

Aluminum extrusion die have high hardness after heat treatment. Wear-resistant end milling should be used, and cutting speeds should be reduced to prevent tool chipping.

After machining, remove chips from the slot and inspect the slot surfaces for cracks, edge chipping, or other defects to ensure safe lifting.

- 3 Axis Vertical Machining Center

- 3 Axis Hard Line Vertical Machining Center

- 3 Axis 2 Linear One Hard Line Vertical Machining Center

- 3 Axis Linear One Line Vertical Machining Center

- Heat Treatment Vacuum Furnace

- Heat Treatment Oil Quenching Vacuum Furnace

- Heat Treatment Air Quenching Vacuum Furnace